-

ইনজেকশন ছাঁচনির্মাণ পরিষেবা

-

প্লাস্টিক ইনজেকশন ছাঁচনির্মাণ পরিষেবা

-

দ্বৈত শট ইনজেকশন ছাঁচনির্মাণ

-

যথার্থ ইনজেকশন ছাঁচনির্মাণ

-

একক শট ইনজেকশন ছাঁচনির্মাণ

-

ইনজেকশন ছাঁচনির্মাণ ওভারমোল্ডিং

-

ই এম ইনজেকশন ছাঁচনির্মাণ

-

ইনজেকশন ছাঁচনির্মাণ .োকান

-

বৈদ্যুতিন ইনজেকশন ছাঁচনির্মাণ

-

সিলিকন ইনজেকশন ছাঁচনির্মাণ

-

ডাই কাস্টিং পরিষেবা

-

Recebক্লায়েন্ট চায় আপনি তাদের পণ্যটি উত্পাদন করুন কারণ তারা আপনার প্রাক্তন প্রোডাকশনগুলির সাথে ফলাফল নিয়ে খুশি হয়েছিল।

Recebক্লায়েন্ট চায় আপনি তাদের পণ্যটি উত্পাদন করুন কারণ তারা আপনার প্রাক্তন প্রোডাকশনগুলির সাথে ফলাফল নিয়ে খুশি হয়েছিল। -

শনভাল টিমওয়ার্ক - ভাল সরবরাহকারী, দ্রুত ক্রিয়া এবং উভয় পক্ষের ভাল লোকেরা এক সাথে কাজ করছে…।

শনভাল টিমওয়ার্ক - ভাল সরবরাহকারী, দ্রুত ক্রিয়া এবং উভয় পক্ষের ভাল লোকেরা এক সাথে কাজ করছে…। -

ক্রিসপ্রতিক্রিয়া জানাতে যথেষ্ট চিন্তা করার জন্য, আলাদাভাবে চিন্তাভাবনা করার এবং আমাদের সাথে নতুনত্ব উদ্ভাবনের জন্য ধন্যবাদ - এই বিকল্পটি খুঁজতে এখানে এই উপলক্ষে আবারও - আরএনডি-তে আমাদের কাছ থেকে অনেক প্রশংসা হয়েছে,

ক্রিসপ্রতিক্রিয়া জানাতে যথেষ্ট চিন্তা করার জন্য, আলাদাভাবে চিন্তাভাবনা করার এবং আমাদের সাথে নতুনত্ব উদ্ভাবনের জন্য ধন্যবাদ - এই বিকল্পটি খুঁজতে এখানে এই উপলক্ষে আবারও - আরএনডি-তে আমাদের কাছ থেকে অনেক প্রশংসা হয়েছে,

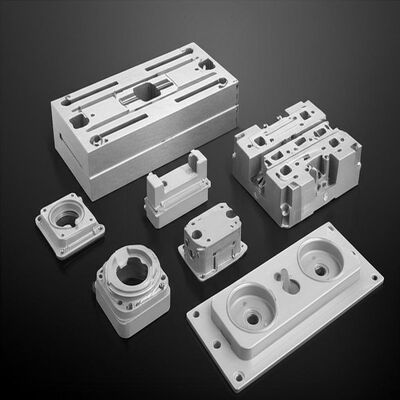

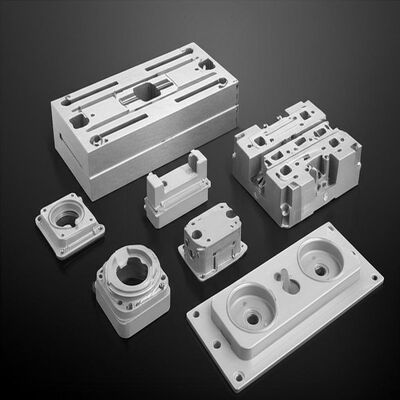

KLM Tooling Base Injection Molding Service for Fast Turnaround Plastic Component Production with 300,000-500,000 Shots Mold Life

বিনামূল্যে নমুনা এবং কুপন জন্য আমার সাথে যোগাযোগ করুন.

হোয়াটসঅ্যাপ:0086 18588475571

wechat: 0086 18588475571

স্কাইপ: sales10@aixton.com

আপনার কোন উদ্বেগ থাকলে, আমরা 24-ঘন্টা অনলাইন সহায়তা প্রদান করি।

x| Mold Base | LKM, HASCO, DME | Volume Production | Available |

|---|---|---|---|

| Tolerance | ±0.01 Mm To ±0.1 Mm | Design Software | UG, Pro/E, AutoCAD, Solidworks |

| Product Material | Plastic | Mold Life | 300,000-500,000 Shots |

| Base | KLM Tooling Base | Finish | None |

| বিশেষভাবে তুলে ধরা | KLM Tooling Base Injection Molding Service,Fast Turnaround Plastic Component Production,300,000-500,000 Shots Mold Life Injection Moulding Service |

||

Product Description:

Our Injection Molding Services provide high-quality, precise, and efficient solutions for manufacturing plastic components tailored to your specific needs. Whether you require standard or customized parts, our expertise in Injection Molding Service ensures that each product meets stringent quality standards and delivers excellent performance. We specialize in producing parts in black as well as customized colors, allowing for flexibility in design and aesthetic appeal to suit various applications.

One of the key advantages of our Injection Molding Service is the use of durable and reliable mold bases from leading manufacturers such as LKM, HASCO, and DME. These mold bases guarantee enhanced stability and precision during the molding process, contributing to superior product quality and consistency. With a mold life ranging between 300,000 to 500,000 shots, our molds are engineered for longevity and cost-effectiveness, ensuring that you receive the best return on your investment.

Our packaging solutions are designed to ensure that your injection molded parts arrive safely and in perfect condition. We provide suitable safe packaging tailored to the delicate nature of plastic parts, preventing damage during transportation and storage. This attention to detail reflects our commitment to customer satisfaction and product integrity.

In addition to Injection Molding Service, we also offer complementary Plastic Extrusion Service and Thermoplastic Molding Service, making us a versatile partner for all your plastic manufacturing needs. Our Plastic Extrusion Service is ideal for creating continuous profiles with consistent cross-sections, while our Thermoplastic Molding Service caters to the production of complex and high-performance thermoplastic components. Together, these services enable us to provide comprehensive plastic manufacturing solutions that cater to diverse industry requirements.

Our Injection Molding Services cater to a broad range of applications, delivering injection molding parts that are widely used across various industries including automotive, consumer electronics, medical devices, and household goods. The precision and repeatability of our processes ensure that every injection molded part performs reliably in its intended application. Whether you need small intricate parts or larger components, our advanced injection molding technology can accommodate your requirements efficiently.

We understand the importance of customization in injection molding projects. That is why we offer black colored parts as standard, along with the option for customized colors to meet your specific design or branding needs. This flexibility enhances the aesthetic value and functionality of your products, helping you stand out in the competitive marketplace.

Our commitment to quality, supported by the use of premium mold bases such as LKM, HASCO, and DME, combined with a mold life of up to 500,000 shots, ensures that your production runs smoothly and consistently. This durability reduces downtime and maintenance costs, making our Injection Molding Service not only effective but also economically advantageous.

Choose our Injection Molding Service for reliable, high-quality plastic components delivered with suitable safe packaging, ensuring your parts arrive in optimal condition. With our extensive experience in Injection Molding, Plastic Extrusion, and Thermoplastic Molding Services, we are well-equipped to support your project from concept to completion, delivering superior injection molding parts tailored to your unique requirements.

Technical Parameters:

| Color | Black Customized Color |

| Color Options | Custom Colors Available |

| Surface Finish | Matte, Glossy, Textured, Painted |

| Tolerance | ±0.01 Mm To ±0.1 Mm |

| Equipment | CNC, EDM, Wire-Cutting, Etc. |

| Design Software | UG, Pro/E, AutoCAD, Solidworks |

| Base | KLM Tooling Base |

| Application | Injection Molding Parts |

| Product Material | Plastic |

| Volume Production | Available |

Applications:

OEM Injection Molding Services offer a comprehensive solution for manufacturing high-quality injection molding parts tailored to various industrial needs. Certified with ISO90001, our services ensure exceptional precision and consistency, meeting the strictest quality standards. With a minimum order quantity (MOQ) of just 1 set, we provide flexible production options suitable for both prototype development and large-scale volume production.

Our Injection Forming Service is ideal for producing intricate thermoplastic components with tight tolerances ranging from ±0.01 mm to ±0.1 mm. Utilizing advanced equipment such as CNC machines, EDM, and wire-cutting technologies, we can achieve superior mold accuracy and surface finish. This makes our thermoplastic molding service perfect for automotive parts, consumer electronics, medical devices, and other applications where durability and precision are paramount.

In addition to thermoplastic molding, we also specialize in Thermosetting Molding Service, catering to industries requiring heat-resistant and chemically stable components. Our expertise allows us to handle complex mold designs and customized colors, including black and other tailored color options, enhancing the aesthetic and functional properties of molded parts.

Packaging is handled with utmost care, utilizing sturdy metal pallets to ensure safe transportation and storage. Our supply ability stands at 10 sets per month, with a typical delivery time of 45-50 days, providing reliable scheduling for your production timelines. Pricing is open to negotiation, allowing us to accommodate various budget requirements and project scopes.

Payment terms are straightforward, primarily via T/T, facilitating smooth and secure transactions. Whether you require single prototypes or full-scale manufacturing runs, our Injection Molding Services combine advanced technology, stringent quality control, and flexible customization to deliver outstanding results across diverse application occasions and scenarios.

Customization:

OEM Injection Molding Services offer comprehensive product customization solutions with a focus on quality and precision. Certified under ISO90001, we ensure that every product meets rigorous quality standards. Our minimum order quantity is MOQ 1 Set, allowing flexibility for both small and large production runs. Pricing is available upon negotiation to best suit your project needs.

We specialize in Thermoplastic Molding Service, Thermoforming Service, and Injection Forming Service, utilizing advanced design software such as UG, Pro/E, AutoCAD, and Solidworks to create precise and innovative plastic components. Our products are made from high-quality plastic materials with tolerance levels ranging from ±0.01 mm to ±0.1 mm, ensuring excellent dimensional accuracy.

Custom colors are available to match your specific requirements, and we provide packaging details with secure metal pallets to ensure safe delivery. Our supply ability is 10 sets per month with a typical delivery time of 45-50 days. Payment terms are T/T, providing a convenient and reliable transaction process. Choose OEM for your injection molding needs and experience exceptional product customization services.